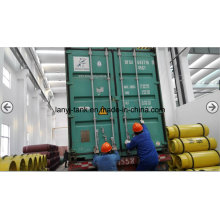

840L 573kg Steel Welding Refillable Gas Cylinder for Liquified Chlorine

- Place of Origin:

- China

- Supply Ability:

- 10000

- Certificate:

- National Standard

Basic Info

Model No.: YP840Y-0

Product Description

Model NO.: YP840Y-0 Application: Liquefied Gas Pressure: 1.6MPa≤p<10.0MPa Pressure Level: Medium Pressure (1.6MPa≤p<10.0MPa) Total Length: 2070-2110mm Life: 12 Years Certification: National Standard Trademark: lanyi Specification: 840L HS Code: 73110090 Function: Storage Pressure Vessel Material: HP345 GB6653 Storage Medium: Liquid Chloride Condition: New Inner Dia: 800mm Body Thickness: 12mm Colour: Green Transport Package: Customized Origin: China Our company is China's largest in low pressure welding Gas Cylinder manufacturer, is the national standard

GN5100-2011 standard responsible for drafting unit,welding gas cylinder production and sales of the national

market more than 45%, and 90% for export welding gas cylinder design, manufacturing. Five types of welding

gas cylinder has nine times by the national,provincial an ministry as high quality products, the products are ex-

ported to the west Asia, the middle east,western Europe,southeast Asia,Japan,Korea,Germany, the United stat-

es and other countries and regions, for the domestic welding gas cylinder's biggest export enterprise. In octobe2001 by the Chinese entrepreneurs assosiation awarded the "welding gas cylinder head of the national industry"

honorary title.

SPECIFICATION:

1 The cylinder should be manufactured,inspected and accepted according to GB5100 welded /steel/gas cylinder

2 The longitdinal and circumferential seams must be welded automaticly by electric-arc welding ,the tensile strengthof joints must be not less than minimum value required.

3 The longitdinal and circumferential welds welds must be examined by ≥20% X-ray radiagraphy.

4 The cylinder must be subjected to heat treatment to relieve stress entirely after all welding

operation have been completed.

5 The cylinder must withstand a hydrostatic test to 45bar without leakage and deform after

heat treatment. Dry the internal surface after testing.

6 The cylinder must withstand a pneumatic test to 15bar with leakage after hydrostatic test.

7 Internal surface must be subjected to rust cleaning before assembly an external surface

must be subjected to shot blasting after assembly.The cylinder must be coated with anti-

corrosion primer and yellow finish paint.

8 Tread seal should be winded with PTFE.

9 Q345R can be used as material of ends and shell .

Contact us if you need more details on Hydraulic Cylinder. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Liquid Chloride Container、Liquified Gas Cylinder. If these products fail to match your need, please contact us and we would like to provide relevant information.

GN5100-2011 standard responsible for drafting unit,welding gas cylinder production and sales of the national

market more than 45%, and 90% for export welding gas cylinder design, manufacturing. Five types of welding

gas cylinder has nine times by the national,provincial an ministry as high quality products, the products are ex-

ported to the west Asia, the middle east,western Europe,southeast Asia,Japan,Korea,Germany, the United stat-

es and other countries and regions, for the domestic welding gas cylinder's biggest export enterprise. In octobe2001 by the Chinese entrepreneurs assosiation awarded the "welding gas cylinder head of the national industry"

honorary title.

SPECIFICATION:

1 The cylinder should be manufactured,inspected and accepted according to GB5100 welded /steel/gas cylinder

2 The longitdinal and circumferential seams must be welded automaticly by electric-arc welding ,the tensile strengthof joints must be not less than minimum value required.

3 The longitdinal and circumferential welds welds must be examined by ≥20% X-ray radiagraphy.

4 The cylinder must be subjected to heat treatment to relieve stress entirely after all welding

operation have been completed.

5 The cylinder must withstand a hydrostatic test to 45bar without leakage and deform after

heat treatment. Dry the internal surface after testing.

6 The cylinder must withstand a pneumatic test to 15bar with leakage after hydrostatic test.

7 Internal surface must be subjected to rust cleaning before assembly an external surface

must be subjected to shot blasting after assembly.The cylinder must be coated with anti-

corrosion primer and yellow finish paint.

8 Tread seal should be winded with PTFE.

9 Q345R can be used as material of ends and shell .

| Technical Characteristics | |

| nominal working pressure kgf/cm2 | 20 |

| hydrostatic test pressure kgf/cm2 | 45 |

| operating temperature (ºC) | -40~60 |

| naminal water capacity (L) | 840 |

| contents | cl2 |

| maximum permissble filling weght (kg) | 1000 |

| joint efficiency | 0.9 |

| corrosion allowance (mm) | 2.4 |

| yield temperature of fusible plug (ºC) | 90+5 |

| Body Material | ||||||||||

| material | mechanical properties | | ||||||||

| σb(Mpa) | σs(Mpa) | δ5 | | C | Mn | Si | S | P | P+S | |

| HP345 GB6653 | ≥510 | ≥345 | ≥20 | | ≤0.20 | ≤1.5 | ≤0.35 | ≤0.035 | ≤0.035 | ≤0,06 |

| Q345R GB713 | 510-640 | ≥345 | ≥21 | | ≤0.20 | 1.20-1.60 | ≤0.55 | ≤0.015 | ≤0.025 | |

Product Categories : Gas Cylinder

Premium Related Products

Other Products

Hot Products

3 Axles 50000L Fuel Tank Semi Trailer4lines 8axles 120tons Low Boy Transportation Semi Truck Lowbed Trailer25-60m3 Tanker Semi Trailer Fuel Stainless Steel TankFuel Tanker Transport Tank Trailer (25-60M3 Optional)Multi-Lines Low Bed Modular Trailer for Heavy Equipment TransportEquipment Transport Detachable Gooseneck Front Loading Lowbed Hydraulic Semi Trailers35ton 40feet Hydraulic Skeleton Container Tipping Semi Trailer3axle U Shape Front Lifting Dump Tipper Tipping Truck Semi TrailerDouble Deck Container Super Link Cargo Transport Semi TrailerCommercial Vehicle Aluminum Alloy Fuel Oil Tank Tanker Semi TrailerHigh Flat Bed Side Wall Flatbed Cargo Box Semi Trailer40ft Container Transport Flatbed Platform Semi Truck Trailer3 Axles Heavy Duty Equipment Transport Low Bed Trailer50, 000L Carbon Steel Middle Pressure 18bar Chemical Storage Tank for Ammonia, Chlorine, Refrigerant GasHigh Quality Liquid Chlorine Gas Cylinder with Valves20FT 25000L High Strength Carbon LPG Tank Container at Reasonble Price